The Simple Fix You Can't Ignore: Addressing Missing Pole Fillers in Electrical Switchboards for Safety

What is a Pole Filler?

A pole filler is a material used to insulate and fill gaps around electrical components within a switchboard or other electrical enclosures. Its primary function is to ensure that there are no exposed live parts that could pose a risk of electric shock or electrocution.

The two pictures above show missing pole filler, which poses a risk of exposure to live electrical parts.

The two images above illustrate the correct and suitable use of pole fillers.

How to fix the problem of missing or damaged pole filler.

Spotting a missing pole filler might seem like a minor issue, but it’s crucial to address it swiftly for your safety and compliance. If you notice a missing pole filler, you’ll need to contact a licensed electrician to rectify the issue. An electrician can correctly install a new pole filler, ensuring that all gaps around live electrical components are properly insulated and the potential exposure to live parts is eliminated.

It’s likely that the electrician will need to briefly isolate the switchboard while they install new pole filler to ensure safe installation.

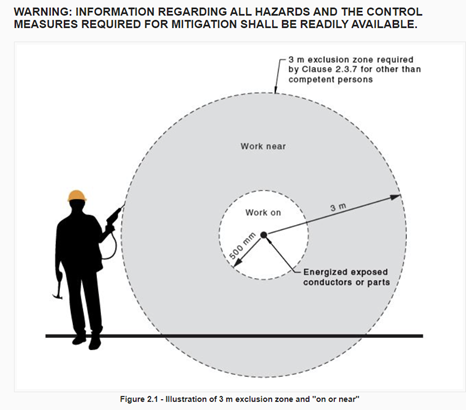

Do not attempt to rectify the issue yourself, as working within 3m of live electrical parts is illegal if you are not a licensed electrical worker.

Why is Pole Filler Installation Considered Live Electrical Work?

Pole filler installation is classified as live electrical work due to the following reasons:

Exposure to Live Parts: When installing pole fillers, the work is carried out directly with or near potentially live electrical components. These components are carrying electrical current, and any accidental contact can be very dangerous. Proper installation of pole fillers ensures that these live parts are properly insulated and protected.

Regulatory Requirements: AS 4836, outlines the work zones and requirements for licensed and competent workers. This standard specifies that work on live or near exposed parts of an installation must be performed by a licensed electrician. This is to ensure that all safety protocols are followed and that the work meets regulatory requirements.

Find out more: AS 4836:2023 Safety Requirements: Working Near Electrical Installations and Managing Work Zones

Please see below the AS 4836:2023 safety requirements for working near electrical installations, including guidelines for managing work zones around energized conductors. Note that these extracts should be considered in the context of the entire standard.

AS 4836:2023

2.1 General

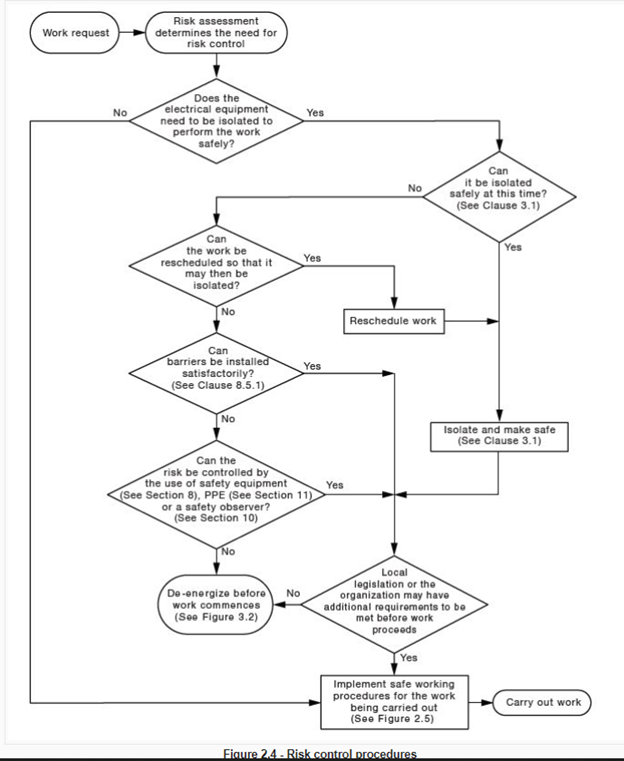

Before work is commenced on or near any electrical installation or equipment, a competent person shall determine whether it is safe to do so. This is achieved by applying a risk management system. All work shall be planned and organized to minimize the risk associated with the work.

The most effective way to control risk is to eliminate it. If a risk assessment indicates that risks cannot be sufficiently controlled to enable the work to be performed safely, then the work shall not proceed.

2.3.7 Work zone

If any person is required to work within 3 m of energized exposed conductors or parts, a competent person shall identify appropriate risk treatments (see Figure 2.1).

Safety shall not be compromised because of operational pressures to carry out the work.

Figure 2.2 depicts the 500 mm work zone for work on low-voltage (LV) and extra-low voltage (ELV) equipment within an enclosed switchboard panel. The 500 mm work zone is shown in the circle.

Energized conductors and live conductive parts do not pose a significant risk when the door of the cabinet in which they are contained is closed. Therefore, when the cabinet door is closed, the internal components are not considered to be part of the work zone and may remain energized even if they are within the exclusion zone depicted in Figure 2.1.

NOTE 1 In some cases, the identification and possibility of encroaching within 3 m of energized exposed conductors or parts will be obvious, e.g. overhead lines and cables and crane collector rails. In other cases, it will not be immediately obvious, e.g. power tools drilling into structures (see Clause 8.3). Work equipment may extend into the 3 m distance, e.g. with ladders (see Clause 8.4).

If you have any questions, please don’t hesitate to contact us at admin@ecotag.com.au, call (08) 6118 7418 or reach out to your licenced electrical contractor.